Beams2D#

Version |

1 |

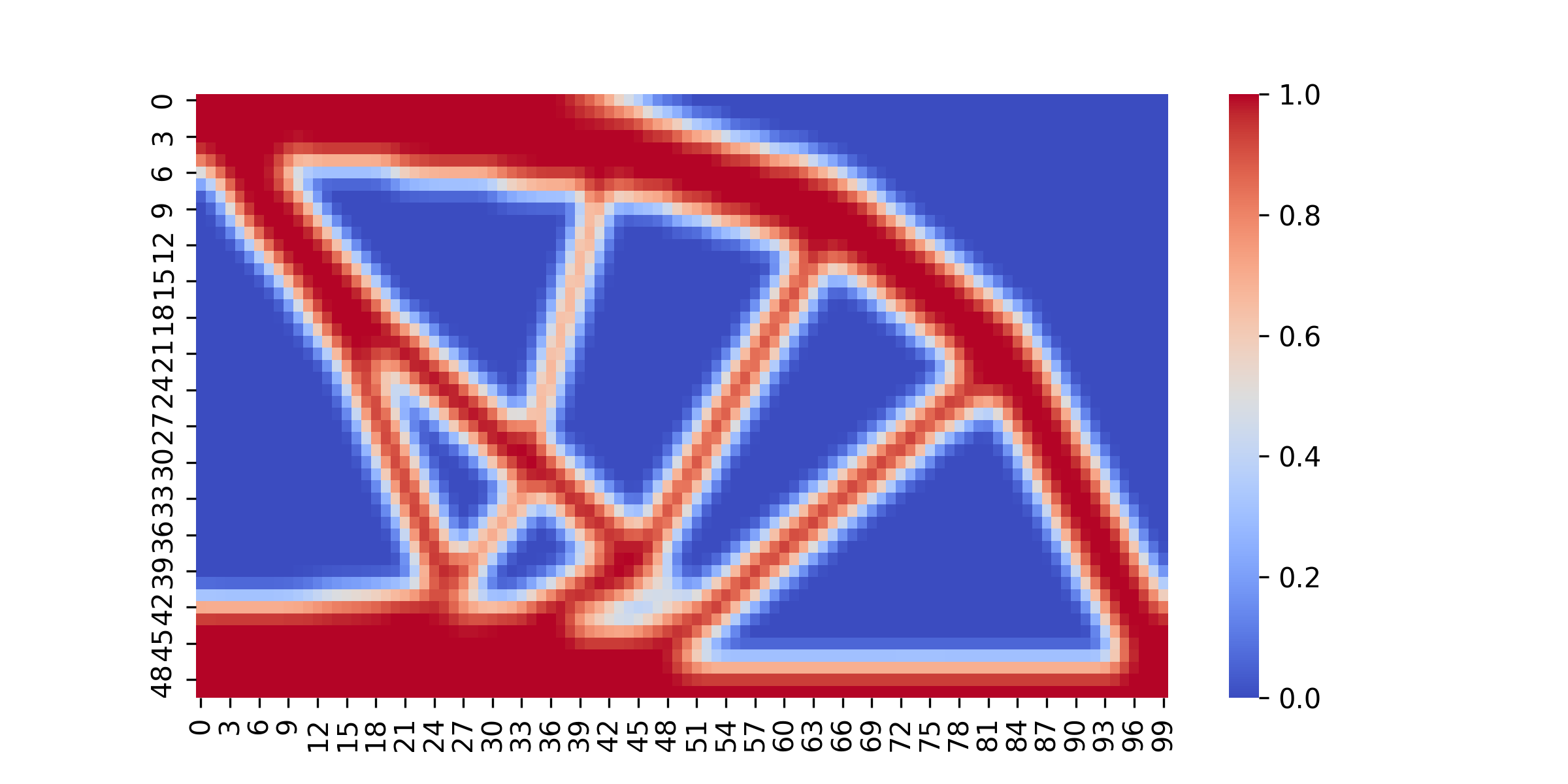

Design space |

|

Objectives |

c: ↓ |

Conditions |

volfrac: 0.35 rmin: 2.0 forcedist: 0.0 overhang_constraint: False |

Dataset |

|

Import |

|

Beam 2D topology optimization problem - Version 1 (v1).

v1#

This version augments v0 by fixing a minor detail in the v0 warm-start optimization process. Specifically, when warm-starting from a provided design, a small epsilon value is added to avoid zero-density values that could lead to gradient issues. The datasets themselves remain unchanged.

All other behavior is identical to v0. See v0.py for full baseline documentation.